-

The MB/GPW Spare Parts Kit, Tools

Kit,

Standard Issue Equipment &

Accessories,

Special Issue Equipment &

Accessories Page

Please don't pirate my pictures or text. Ask

my permission.

Copyright

© 1998-2012 Brian French. All Rights Reserved

Spare Parts Kit

| Item Nomenclature |

Fed # /

MFG. # |

Willys # |

Ford # |

Storage Location |

| Bag, Spare Parts |

8-B-11 |

A-7686 |

GPW-17008 |

Glove Box *1 |

| Belt, Fan |

33-B-76 / Gates

79T |

A-1495/A-9490 |

GPW-8620 |

Bag, Spare Parts |

| Caps, Tire Valve, boxed, (5x #GPW-1720) |

8-C-650 |

A-7681 |

GPW-18322 |

Bag, Spare Parts |

| Cores, Tire Valve, boxed, (5x #B-1725) |

8-C-6750 |

A-7682 |

GPW-18320 |

Bag, Spare Parts |

| Lamp, Incandescent, 6-8v, 3cp |

17-L-5215 / Mazda

63 |

A-8385 |

B-13166 |

Bag, Spare Parts |

| Lamp-Unit, BO Stop, 6-8v, 3cp |

8-L-421 |

A-1078 |

GP-13485A |

Bag, Spare Parts |

| Lamp-Unit, BO Tail, 6-8v, 3cp |

8-L-415 |

A-1075 |

GP-13491A |

Bag, Spare Parts |

| Lamp-Unit, Service Tail & Stop, 6-8v, 3-21cp |

8-L-419 |

A-1074 |

GP-13494A |

Bag, Spare Parts |

| Pins, Cotter, (Kit) |

42-P-5347 |

A-7683 |

GPW-18318 |

Bag, Spare Parts |

| Plug, Spark |

17-P-5365 /

Champion-J9 Autolite-AN7 AC-44 Firestone-17-P-5365

G503-03-40680 |

A-538 |

GPW-12405 |

Bag, Spare Parts |

| Tape, Friction (Roll) |

17-T-805 |

A-7684 |

GPW-17058 |

Bag, Spare Parts |

| Wire, Iron, 1/4 lb. Spool |

22-W-650 |

A-7685 |

GPW-17060 |

Bag, Spare Parts |

| *Bag, Key (with two H-700 keys) |

|

|

GPW-17082 |

Glove Box *2 |

| *Cap, Drain, Sump, Gas Tank Well |

|

A-3055 |

GPW-1111322 |

Glove Box *3 |

| *Plug, Drain, Floor, Body |

|

A-5120 |

358019-S 1/4" plug |

Glove Box *2 |

*1 ~ Right Rear Tool Box on Slatgrill MB models.

*2 ~ Not a spare part, but stored with

spare parts when not in use.

*3 ~ Not a spare part, but stored with

spare parts when not in use. Normally front cap was installed on sump,

while the rear cap was stored in glove box. The rear cap was installed

on sump only when fording water.

Bag, Spare Parts - A small bag sewn from light OD green cotton

cloth. Closed at the top by a drawstring. Stored in glove box on most jeeps

or in rear tool storage box on the early slatgrill MB's without a glove

compartment..

Belt, Fan - A coiled Fan Belt found marked in 3 versions.

-

Federal Ordnance Stock #,

-

Willys were marked in orange rubber ink "WILLYS A-9490 B.F. GOODRICH"

-

Ford's were marked in raised lettering "FORD GPW-8620"

Cap, Tire Valve - Extra Tire Valve Stem Cores & Caps were included.

Core, Tire Valve - Extra Tire Valve Stem Cores & Caps were

included.

Lamp, Incandescent - Small 6v bulb that fits both the Dash (Instrument)

Lamps and the Blackout Marker Lights.

Lamp-Unit, BO Stop ~ Lamp-Unit, BO Tail ~ Lamp-Unit, Service Tail

and Stop - B/O taillight assemblies consisting of metal housing, bulb,

and lens in one unit.

Pin, Cotter - a small cardboard box of many various size cotter

pins was included. Found marked in 3 versions.

-

in cardboard box marked with "Federal Ordnance Stock #42-P-5347 US

ARMY"

-

Willys have been found in a small metal canister with lid

-

Ford's were in cardboard box marked with "FORD GPW-18318"

Plug, Spark - Spark Plug with Gasket. Also found in several brand

versions.

Tape, Friction - A roll of black friction tape (early form of

electrical tape) that is 4 1/4" in diameter x 3/4" wide.

Wire, Iron, ¼ lb. Spool - a coil of easily bent iron

bailing wire described as "iron, annealed wire, 22ga. x 1/4 lb.

spool coil".

*Bag, Key (H-700 key) - a small cotton bag was included with

shipped jeeps. The bag was stored in the Glove Compartment. The bag contained

two H-700 keys which were used on the following;

-

Tool Box Locks (2)

-

Spare Tire Lock

-

Ignition Switches (early Keyed type)

-

Glove Box Lock (early Keyed type)

-

Black Out Light Switch on MBT Trailer (shown in manuals using base of key,

not key shaft). 1/4ton Bantam and Willys trailers (MBT / T-3) used the

same black out lights as jeeps did, however, switching between normal and

blackout lights on the jeep pulling the trailer did not affect the

status of the lights that were running on the trailer. The trailer

had its own light switch mounted to the front passenger side box frame.

Here is a photo

showing the small WWII MBT Jeep Trailer B/O Light Switch mounted in the

front of the lower passenger side. There was a small disc (door) that

swiveled out of the way to reveal a small set screw that can be turned

using the butt end of the Jeep H-700 Key to switch between running lights

and B/O lites.

*Cap, Drain, Sump, Gas Tank Well - Although not a spare part, it

was intended to be stored with the items in the Spare Parts Kit on the

jeep in the glove compartment. The jeep's gas tank sump (the well in the

body that the gas tank sat in) had a front & rear drain assembly.

Both drains consisted a neck (similar to a radiator neck #A-3056, #GPW-1111323)

held on by 3 rivets each, and a removable Cap (similar to a radiator cap).

The front cap was supposed to be installed at all times to keep out debris

kicked up by the front tires, except when flushing out the well. The rear

cap was supposed to be removed and stored in the glove box, except when

crossing streams or other water fording. After fording the rear cap would

be removed allowing the sump to drain. See TM 9-803, pg. 36, item #24.

*Plug, Drain, Floor, Body - Although not a spare part, it was

intended to be stored with the items in the Spare Parts Kit on the jeep

in the glove compartment. The jeep's front floor pan (the area of the body

that the occupants feet sat in) had a drain assemblies. One on the driver's

and one on the passenger's side. Both consisted of a pressed in fitting

(similar to a round captive nut) and a removable Plug (think pipe plug).

The plugs were supposed to be installed in dry periods, and be removed

and stored in the glove box during wet periods, such as rains, washings

or when crossing streams or other water fording. 1942 GPW Parts Manual

TM-10-1348 lists them as 1/4" Plug #358019-S, with a plain raw steel finish.

TM-10-1513 lists them as being brass.

Tools Kit

| Item Nomenclature |

Fed #

/ MFG. # |

Willys # |

Ford # |

Storage Location |

| Adapter, Grease Gun (Early, Short) |

|

A-6151 |

GPW-17126 |

Bag, Tool |

| Adapter, Grease Gun, (Mid-Late, Long 2-piece) |

41-A-14-800 - Alemite #6344

- Ord.#A-349744 |

A-11765 |

GPW-17126 (a) |

Bag, Tool |

| Adapter, Grease Gun, (Late, Long 1-piece) |

41-A-14-825 - Alemite #6517 |

|

GPW-17126-B |

Bag, Tool |

| Bag, Tool |

41-B-15 |

A-372 |

GPW-17005 |

Right Rear Tool Box |

| Chains, Snow, Type D, 6.00 x 16 (Qty 4) |

8-C-2538 |

A-1133 |

GPW-18136 |

4 Chains in 2 Chain Bags, Right Rear Tool Box |

| Crank, Hand, Engine Starting |

8-C-8322 |

A-289 |

GPW-17036 |

Hangs from clamp on inside of Rear Body Panel |

| Extinguisher, Fire, (1 Qt. Sprayer) |

58-E-202 |

A-616 |

GPW-17100A |

Inside Cowl, Bracket on Driver's side *4 |

| Gauge, Tire Pressure (gage) |

8-G-615 - Schrader

7188B |

A-6855 |

GPW-18325 |

Bag, Tool *5 |

| Gun, Grease, Push Type*, 9oz (Early) ~ pre 4/1944 |

41-G-1344-40 - Alemite

#5585 |

A-213 |

GP-17125 |

Left Rear Tool Box |

| Gun, Grease, Lever Type*, 16oz (Late) ~ post 3/1944 |

41-G-1330-60 Lincoln

#1078, ARO #2040

Alemite #6593 (body), Alemite #6594

(ass'y) |

|

G8T-17125 |

Engine Compartment, under hood in bracket on Driver's side |

| Hammer, Machinist's 16oz Ball Peen |

41-H-523 |

A-373 |

GP-17042 |

Bag, Tool |

| Jack, Screw type, 1 1/2 ton* |

41-J-66 #200-W-G |

A-1240 |

GPW-17080 |

Left Rear Tool Box |

| Oil Can, Straight Spout, 1/2 pint push bottom |

13-O-1530 |

A-379 |

GP-17038 |

Engine Compartment, Driver's Firewall in Bracket |

| Pliers, Combination, Slip Joint, 6 inch, Wire Cutting |

41-P-1650 |

A-374 |

GP-17028 |

Bag, Tool |

| Puller, Wheel Hub (flange) |

41-P-2962-700 |

A-1339 |

GPW-17090 |

Left Rear Tool Box |

Pump, Tire

with Blower Fitting (air chuck & nozzle) |

8-P-5000 |

A-6899

A-7511 |

GPW-17025 |

Under Rear Seat Pan, in Brackets *6 |

| Screwdriver, Common, Heavy Duty, 6 inches |

41-S-1076 |

A-375 |

GP-17020 |

Bag, Tool |

| Wrench, Auto, Adjustable, 11 inches |

41-W-449 |

A-377 |

GP-17021 |

Bag, Tool |

| Wrench, Brake Bleeder, Screw (Open End, Single sided) |

41-W-1596-125 |

A-5130 |

GPW-17030 |

Bag, Tool |

| Wrench, Crescent, 8 inches |

41-W-486 |

A-376 |

GP-17023 |

Bag, Tool |

| Wrench, Socket, Fluted Head Set Screw |

41-W-2459-500 |

A-1492 |

GPW-17091 |

Bag, Tool |

| Wrench, Hub, Wheel Bearing Nut, (2 1/8" socket) |

41-W-3825-200 |

A-692 |

GP-17033 |

Left Rear Tool Box |

| Wrench, Open End, (No.723) 3/8" by 7/16" |

41-W-991 |

A-596 |

GP-17043 |

Bag, Tool |

| Wrench, Open End, (No.25) 1/2" by 19/32" |

41-W-1003 |

A-597 |

GP-17044 |

Bag, Tool |

| Wrench, Open End, (No.27C) 9/16" by 11/16" |

41-W-1005-5 |

A-598 |

GP-17045 |

Bag, Tool |

| Wrench, Open End, (No.28D or 28S) 5/8" by 25/32" |

41-W-1008-10 |

A-599 |

GP-17046 |

Bag, Tool |

| Wrench, Open End, (No.731A) 3/4" by 7/8" |

41-W-1012-5 |

A-600 |

GP-17047 |

Bag, Tool |

| Wrench, Drain Plug, Square, 3/8 |

41-W1962-50 |

A-1100 |

GPW-17062 |

Bag, Tool |

| Wrench, Spark Plug, with Handle |

41-W-3335-30 or

40 or 50*

(2/1944) TM-9-803 |

WO-637635 |

GPW-17017-A

(1942 + 1944) |

Bag, Tool |

| Wrench, Handle, Spark Plug |

|

WO-306715 |

GPW-17011-A |

Bag, Tool |

| Wrench, Wheel Lug/Jack Handle, 49/64" |

41-W-3837-55 (#41-W-3837-25) #24832 |

A-348 |

GPW-17035 |

Right Rear Tool Box |

| *Bolt, Square Head, Rear Axle Puller (4) |

|

|

|

Installed in 2 tapped holes on each rear axle hub *7 |

| **Compressor, Shock Absorber Grommet |

41-C-2554-400 - Monroe

#MAS-1148 |

|

|

Left Rear Tool Box or Mechanic's Tool Chest *8 |

| **Lifter, Valve - Valve Compressor /Adjusting Tool |

41-L-1410 |

|

|

Left Rear Tool Box or Mechanic's Tool Chest *8 |

| **Wrench, Tappet, Double End, 11/32" x 17/32" |

41-W-3575 |

|

|

Bag, Tool *8 |

***Chest, Tool, Mechanic's (Portable Tool Box)

Box, Tool, S., loose tray, olive drab, enameled, 21"

x 8 1/2" x 7 5/16" |

41-B-1833

41-B-1840 |

|

|

Motor Pool Item, not stored on jeep *8 |

| ***Pan, (oil) Drain, Iron, 4 Gallon capacity |

41-P-125 |

|

|

Motor Pool Item, not stored on jeep *8 |

| ***Sockets and Ratchet Socket Sets |

|

|

|

Motor Pool Item, not stored on jeep *8 |

*4 ~ Inside cowl, from bracket on passenger's

side on Slatgrill MB and Ford Script GPW models.

*5 ~ Also, found: in Glove Box; in homemade

pouch on side of front seat; in homemade clips on glove box door, or on

top of front grill air deflector panel. per original WWII

issues of Army Motors.

*6 ~ Early Script Fords and Slatgrill

MB's did not have brackets welded underneath rear seat lower pan. Pump,

if issued, would of had to be wedged somewhere.

*7 ~ Word of mouth from many veterans,

jeeps in the wild having them on, NOS examples found in Jeep Dealers' inventory.

*8 ~ Special Tools issued to

2nd echelon - only a few would be issued to a group of jeeps. Motor Pool

item. fig. 18-94

Adapter, Grease Gun - #41-A-14-800 or #41-A-14-825 - This tool

is an extension that slips onto the end of the grease gun that allows the

nose of the grease gun to get into tight places such as the drive shaft

U-joints, and it develops extra pressure. The tool fits all 3 types of

grease guns (Push & Lever action).

There are 4 Versions of Adapters.

-

The early short/small "thin stem, rigid type" adapter. It looks like a

tiny 'fireman's hose nozzle'. It is a simple, short, piece of milled metal

that is hard to use because of it's tendency to wobble and fall off of

the grease gun. GPW Part #17126, Willys part #A-6151,

-

The Mid-Late two piece tube shaft "thin stem, sleeve type" having

a longer nose than the early adapter. #41-A-14-800 (10/1944). Alemite part

#6344, Willys part #A-11765. It is longer, approx. 6" long, cadmium plated,

made of multiple pieces of stamped & machined metal, and has a sliding

collar over the Zerk fitting at the rear (where it mates to the Grease

Gun) to help hold it steady on the Grease Gun. The tube shaft was in 2

pieces and could be unscrewed. The reason for needing it to unscrew is

unknown to me. Perhaps it is for greasing a different type of grease fitting.

-

The Late one piece tube shaft "thin stem, sleeve type" having a

longer nose than the early adapter. #41-A-14-825. Alemite part #6517.

Ford part #GPW-17126-b (10/1944). It is longer,

approx. 6" long, cadmium plated, made of multiple pieces of stamped &

machined metal, and has a sliding collar over the Zerk fitting at the rear

(where it mates to the Grease Gun) to help hold it steady on the Grease

Gun.

-

Very late Cup type adapter. This adapter was cadmium

plated, very short, approx. 1" by 1/2", (It did not nee to be as long as

previous Grease gun Adapters since it was used on Late Lever Action Grease

Guns that had a much longer reach to begin with) and machined from round

stock. It appears that this type of Grease Gun Adapter was more like a

'Needle Filler'. Instead of snapping onto the Grease Gun's fitting, the

Grease gun fitting was unscrewed and this "needle filler' was screwed on

in it's place producing a thin, high pressure stream of grease to where

ever you shoved the cone shaped end of this Adapter.

Bag, Tool - #41-B-15 - A heavy OD Green canvas bag approx. 20" long

by 9 3/4" wide constructed in the shape of an envelope with a triangular

closing flap and secured with a 2 straps sewn on the tip of the flap so

the bag can be rolled up and tied closed. Many are stenciled with "BAG,

ASS'Y, TOOL / FED. STOCK No. / 41-B-15".

Chains, Snow, 6.00 x 16 (Qty 4) - #8-C-2358 - 4 Snow Chains

sized to fit a 6:00 x 16 inch tire in 2 canvas Chain Bags are stored in

the Right Rear Tool Box. Two sets of chains were carried on every jeep,

so that all 4 tires would have maximum traction in mud & snow, however

they were the plain twist link chain variety without additional metal pieces

welded on for traction. Willys MB and Ford GPW attachment hardware assemblies

differed. Several contractor brands are noted and there are varieties in

marking on the bags as well.

Crank, Hand, Engine Starting - Both Willys and Ford marked hand

cranks exist. The crank was designed to be used if the starter motor failed.

In use, the hand crank is inserted into a hole in the face of the front

bumper and slides back into a special crankshaft nut that has a round bar

going through the middle of it. The Hand Crank's one-way teeth engages

the bar in the center of the crank shaft nut. The one way teeth allow the

engine to be turned over (by hand) by turning the handcrank. When

the engine fires up, the one-way teeth kick the handcrank off the bar on

the engine crankshaft nut.

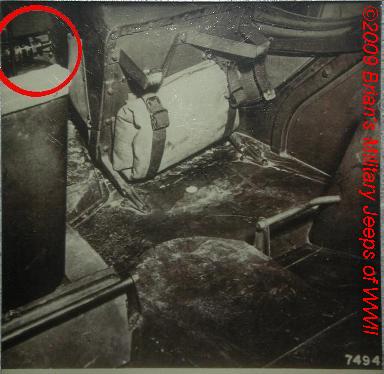

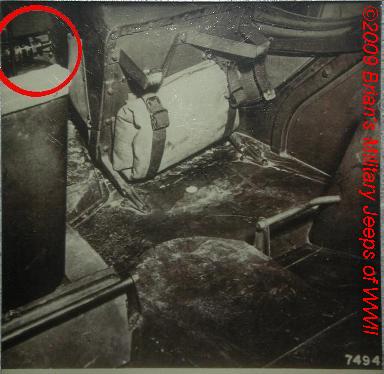

Photograph

of Jeep Handcrank & mounting clamp, brackets, and wingnut in correct

mounting position on WWII Jeep.

Hand Crank Brackets - The Handcrank

hung at an angle against the inside of the Rear Body Panel. It hangs vertically

on a bracket with a threaded stud on it welded to the rear body panel.

Over this threaded stud a curved clamp bracket (#A-2853) is placed wrapping

around the round metal of the hand crank. The Clamp is secured by

a wing nut at the top. Welded to the floor pan are 2 small "L" shaped brackets

which also secure the lower ends of the crank.

Fire Extinguisher, 1 Qt. - #58-E-202 - A brass liquid

pump sprayer, made by several manufacturers. The Fire Extinguisher mounted

in a bracket, [Early #GPW-17108, #GPW-17103-A (2/1942)

or Late #G8T-17103A (10/1944)], on 3 legs (#GPW-17102,

#A-693),

which are then bolted

to the inside cowl of the jeep. There are several versions of early

fire extinguisher brackets, but they appear to have been standardized by

1943 with the universal mount that accepts both center and offset pump

handles. The bracket mounts on the Drivers side for most jeeps, however

the Slatgrill MB and Script GPW had it located on the passenger's side

cowl. Original intructions were to: Aim at fire,

Twist & Pull handle, then pump by hand.

Ford

Factory Assembly Line photo of Ford Fire Extinguisher in Jeep at bottom

of this page.

Photo

of several rare "Ford" script type Fire Extinguishers, next to gray jeep

decontaminator.

Picture

of a Fire Extinguisher mounted in the late standardized Fire Extinguisher

Bracket in the normal (Driver's side) position on the inside cowl.

Picture

of an Early Slatgrill Flat Bottom style Fire Extinguisher Mounting Bracket

in the Early (Passenger's side) position on the inside cowl.

Gauge, Tire Pressure (gage) - #8-G-615 - Service Tire Gauge

- A typical 12 1/2" long heavy duty truck tire pressure gage. Nickel plated

brass or natural brass finish. Many come with a sliding brass ring loosely

attached to the smaller shaft (air tube) portion. The Gauges are stamped

with both the manufacturers name, location, and Patent #'s as well as either

"US PROPERTY / ORDNANCE DEPT." or "US PROPERTY / Q.M.C.".

Most commonly seen is the Schrader brand. Another supplier was the Druce

Bros. Mfg. Co. of Oakland. Calif. Some, but very few, are dated in the

shank.

Grease Guns - Two types of Grease Guns were issued in World

War Two. Both were made to fit Zerk type fittings.

Gun, Grease, Push Type (Early - Mid-War)

~ pre 4/1944 - #41-G-1344-40 / Alemite #5585 /

#A-213 / #GP-17125 - The early type was a pistol grip type

that used hand pressure to push the grease out the nozzle. The pistol grip

was shoved forward pushing the plunger into the grease filled tube

forcing the grease out through the small tube and into the nipple fitting.

It was stored in the left rear tool compartment and was issued until sometime

between March and April 1944 (per 4-1942 TM 10-1348).It

was smaller and held less grease and developed less pressure than the later

Lever Action Grease Gun. Alemite Model #5585 should

be found stamped into the barrel of the body. I have some that are marked

"U.S.N.", most are not marked in any other way. There are two types

of this early model.

The early version (Slatgrill MB's and Script

Fords, and Prototype Jeeps) had a solid black Bakelite plastic pistol grip

rear handle.

The mid-war version was the same overall configuration

with the exception of having a wire loop pistol grip handle. (Bakelite

was being conserved for the war effort).

Gun, Grease, Lever Type (Late) ~ post

3/1944 - #41-G-1330-60 / Alemite #6593

/ #G8T-17125 - The Late type was issued starting sometime

in March or April 1944. It had a larger capacity and was a Lever

Action type Grease Gun and was stored in a special bracket under the driver's

side lip of the hood. Driver's side to be exact. Moving the Grease Gun

from the rear tool compartment meant a cleaner tool compartment. However,

placing the Grease Gun alongside a hot motor can cause the grease to liquefy

and the wind will blow drippings into all sorts of hard to reach places.

If showing your jeep, leave the Grease Gun empty. The most commonly found

ones are from Alemite and marked on the body " Alemite Lever Gun Model

- 6593 Stewart-Warner Corp.". The lever handles can be marked as well.

I have one NOS Grease Gun from Ft. Lewis, Wa that has the Federal Stock

# on it, but it is not a Alemite gun - it looks exactly the same though.

The Lever Action grease guns had a longer reach because of the longer thin

tube. In addition, a rubber hose could be substituted or added if needed.

Photograph

of Late Grease Gun in Grease Gun Mount on Navy WWII Jeep.

Photograph

of Late Lever Action Grease Gun mounted in Grease Gun Bracket under hood

of WWII Jeep.

Photograph

of hood with Grease Gun Bracket removed, showing welded on reinforcements.

Grease

Gun Bracket - A very odd shaped bracket

that is often mistakenly called a fire extinguisher mount by novices.

It looks nothing like a fire extinguisher bracket, or any other bracket

I know of. It is very distinctive. Once you have seen the bracket installed

on a jeep and the perfectly fitting Grease Gun installed in the bracket

you won't forget what it looks like. Often jeeps in the wild will be missing

the hinged arm that goes around the barrel and hand lever. This arm

locks in place with the same type of catch as found on the 1st Aid Kit

mounting Brackets. There are four holes in the bracket for mounting screws

that join up to 2 welded reinforcing plates on the inside of the hood.

From the outside of the jeep, with hood closed, all you will see are the

round heads of the machine screws 8" by 1 1/2" apart.

Hammer, Machinist's 16 oz Ball Peen - #41-H-523 - A standard

1 lb. Ball Peen hammer with a non-painted (bare wood or stained wood) handle

with an overall approximate length of 14". The US Government specifications

called for 14 3/8" with a tolerance of 1/2" either way. However, when hunting

for Jeep hammers, keep in mind that Gov. specs also called for a 11" Adjustable

Wrench, yet Ford GPW's were supplied with 12" MOORE Adjustable Wrenches

- a full 1" off from the governments specifications. The weight class of

a hammer is for its head only, so the actual weight on a scale for the

hammer AND HANDLE, will be 4-6 oz heavier than the stated 16oz. due to

the weight of the wood and the shims holding the head to the handle. So

total combined weights of 1lb 3oz to 1lb 6oz are correct. In addition,

many correct hammer heads have had shorter replacement handles fitted over

the years as well. A short handle will of course drop the combined weight

total. Just be sure that it is a high quality metal head. They would

not have used cheaply made hammer heads, so buy only top quality ones.

The 16oz military issue ball peen hammer has a flat striking surface on

one side (the 'hammer' side) and a round or rounded peening face on the

other side (the 'peen' side). The 'peen' end can be a nice round shape

or a more angular (like the pointy end of an egg) shape. Both are believed

to be correct. These hammers were produced by many companies and these

contractors include; Fairmount, Barcalo Buffalo, Bonney, Williams, Vlchek,

Heller, AFH, True Temper, Vaughn, Craftsman, Bond, and several others.

Many correct hammers will be marked only with the manufacturer's name,

however I do have hammers in my collection with additional markings on

them. They include a few with: "US"; "USAAF"; "QMC"; or "ORD" stamped

on them. I recall seeing a "USN" one as well. I also have a couple of "Ford"

marked hammers, but they are not very common. The "FORD" and/or "F" mark

is usually very faint and hard to see and it was a very thin die. This

probably explains it's rarity as any polishing, wire wheeling, sand blasting,

or painting, or glancing missed blows would have obliterated it. If you

find a "US", "QMC", etc. marked hammer, but it is not the right weight

for a jeep, you should still try to buy it. It is a military hammer

from some other toolkit. Hammers of various sizes were also included

in many other military tool kits and in onboard tool kits of other military

vehicles, and this explains the large number of manufacturers and the wide

variety of markings. There are many people who collect military marked

tools in general. If you don't add it to your personal collection, it makes

for good trading material.

Jack - #41-J-66 - Rectangular base

(square base are post WWII). Round opening on ratchet mechanism. Round

opening is for long end of lug wrench to act as jack handle. (A flat slot

opening is civilian car jack, not a jeep jack). Jack was stored in the

rear fender tool box. It works by inserting the long end of the lug wrench

into a round opening on the top hat of the "T" shaped portion of the jack

and then by ratchet action (left to right) either raises or lowers depending

on how a twistable tab is positioned. The tab is pulled out and twisted

and then released to change from raise to lower. The tab is marked "UP"

and "DOWN". the jack is approx. 6 1/2 " tall, and the base is slightly

larger than 6" by 4". There are photos in manuals for the very earliest

Slatgrill MB and Script Ford GPW Jeeps showing a scissors type jack in

the tool inspection layout. Please contact me if you have any other information

on these early jeep jacks.

Photograph

of Ford GPW Jack with Round top rest pad cup.

Photograph

of Willys MB WWII Jack with Oval top rest pad cup.

Oil Can, Straight Spout, 1/2 pint, push bottom - #13-O-1530 - #A-379

- A typical 1/2 pint click the bottom oil can mounted in a special

bracket

(Holder #GP-17037, #A-313) inside

the engine compartment, on the driver's side firewall near carb & manifolds.

Several manufacturers made them - desired ones being: Eagle or Gem, Noera

and others. One NOS surplus crate containing 100 oil cans individually

wrapped had 5 different manufacturers, 3 types of spouts, and some were

painted OD, others were in black cosmoline, and still others in bare oiled

metal.

Photograph

of 'Gem' Oil Can & Oil Can Bracket mounted in WWII Navy MB/GPW Jeep.

Oil Can Bracket

- #GP-17037 - #A-313 - A

horizontal "L" shaped bracket that was bolted to the firewall under the

hood of a jeep on the drivers side between the engine block and horn with

the oil can spout coming up by the carb. The bottom of the

bracket had a sliding piece on it with 2 raised hooks towards the front.

This part (with the hooks) had a spring attached to it drawing the hooks

back. The oil can was placed into the hooks and pulled forward until the

rear of the oil can's bottom lip caught in a notch at the rear. The

hooks were prevented from retracting by the oil can. The tension from the

hooks kept the oil can in the bracket. Some Oil Can Brackets are "1943"

dated, but the majority are not.

Pliers, Combination, Slip Joint, 6 inch, Wire Cutting -# 41-P-1650

- Standard 6" Pliers that were adjustable to 2 positions through the slip

joint <pivot point>. The very bottom portion of the jaws overlapped

when closed, but did not overlap when opened. This overlap allowed a wire

to be inserted into the gap and cut when hand pressure was applied to the

grip to close the overlap. Several tool companies made appropriote pliers.

They include: CEE TEE, Fairmount, Utica, Barcalo Buffalo, Williams, Vlchek,

MH (McKAIG - HATCH), JP Danielson, Diamond, and Ford. Photos exist in manuals

showing the end of one handle being ground down into a screwdriver tip.

In fact having a screwdriver tip at the bottom of one of the arms is very

common on the "Ford" script pliers. Pliers found NOS in the boxed kits

usually do not have the screwdriver tip, but only a couple of unopened

boxes have been found. So you can say that Pliers came without the

driver tip handle, AND the photos in manuals indicate that they also came

with the screwdriver tip.

Puller, Hub - #41-P-2962-700 - 1/2 cone shaped tool that pulls

the front wheel hub flange off the hub and front axle shaft to allow access

to the axle nuts and wheel bearings. The Tool is a cast iron tool, and

part #'s are cast into it. Ford's have a "F" stamp. The top of the cone

is drilled & tapped for a 3/8 NC bolt to go through. The bolt was not

issued with the tool. You were instructed by the manuals to use one of

the bolts you just removed from the Hub Flange. The bottom of the tool

has a lip which fits around and catches on the Hub Flange. When the bolt

at the top is turned, the bolt proceeds into the cone and makes contact

with the axle shaft face, applying a pressure that pulls the flange off

the splines of the axle shaft.

Pump, Tire, with Blower Fitting (air chuck & nozzle) - #8-P-5000

- There are several versions of Tire Pumps issued. I have 9 different types

in my collection. There are several manufacturers, Walker and Dalton being

the 2 most common. Some manufacturers even made several different

versions of tire pumps. The Pumps were made with a very pronounced "US"

on the top of the left foot pad. (I have one exception, which is marked

"USA" instead of "US"). I have only seen 2 like this. On the top

of the foot pad on the right side was a raised "QMC" or "ORD". You would

want a pump marked by the dept. overseeing jeep procurement at the time

of your jeeps production. Check your Data Plates on the dash. It will say

either Quartermaster Corps, or Ordnance Department. My estimate is that

the QMC's are rarer than the Ord. marked ones as the Ordnance Dept. oversaw

procurement when production was at it's peak. On the end of the rubber

hose was a fitting which screwed on to the Tire Valve Stem. Also on the

rubber hose, secured by a metal chain and metal loop that went around the

hose, was a blower tip fitting. There are more than one variety of the

blower tip. The difference is in the machining, One simple type not often

seen is just a turned down tube treaded at one end, and in the middle of

the tube a groove has been cut and one link of the "S" chain goes tightly

into and around this groove. The other more common fitting is more complicated.

It has two raised ribs on the shaft. Between these two raised ribs is a

smaller metal band that is a retaining loop that is attached to the over

end of the chain. The blower tip was used for such things as drying out

distributor caps, blowing out fuel lines, and filling air mattresses if

the GI was lucky enough to have one.

Tire Pump Mounting Brackets - mid

way in 1942 brackets were installed under the rear seat pan to secure the

Tire Pump & Hose with Blower Tip. First the pump was placed in the

base bracket, which is on the passenger side, and then the pump handle

was brought to the Stud that was welded to the bottom of the seat on the

driver's side. A curved and forked clamp went onto the treaded stud and

a wingnut tightened it down after the other end of the clamp had grabbed

the pump wood handle. Next the rubber hose was wound once around the tube

of the pump and then brought back to the base bracket where the Blower

Tip Fitting went into a small hole punched in a small finger of metal extending

from the base bracket. the fitting of the hose was on one side, and the

Blower Tip fitting on the other side. the Blower Tip Fitting was then inserted

into the hole and the Hose Fitting threaded onto it, thus securing the

hose in place to the base bracket and keeping the hose from sliding around

and getting in peoples feet. Early Script Fords and Slatgrill MB's did

not have Base Bracket (#-A4516) and Clamp (#A-4518)

welded

underneath rear seat lower pan. The Tire Pump, if issued, would of had

to be wedged somewhere, most likely against the handcrank.

Screwdriver, Common, Heavy Duty, 6 inches - #41-S-1076 - An

early wood and metal screwdriver approx. 11 1/4" long. The metal blade

is approx. 6" long. The metal runs the full length with 2 wooden

side grips riveted on. The metal is bare, while the wood grips can be clear

to yellow varnished, while other show up with a med. brown stain finish.

The WWII MB/GPW Jeep manual shows a picture of the screwdriver with "IRWIN

/ MADE IN U.S.A." on the wood handle marked in ink or paint. Other Military

Vehicle and Military Manuals show additional photos of the #41-S-1076 screwdriver

as part of other motor pool mechanics tool kits. The companies that produced

these screw drivers are;

-

TOBRIN

-

RYAN TOOL CO.

-

FEDERAL (Furney Sherwin)

-

FAIRMOUNT

-

LENOX

-

IRWIN

There are 5 variations of markings on the IRWIN screwdrivers:

-

wood handle inked "IRWIN - MADE IN U.S.A."

-

metal shaft marked "IRWIN - US of A - GOV. STOCK

#41-S-1076"

-

metal shaft marked "IRWIN - US of A."

-

metal shaft marked "IRWIN - USA"

-

metal shaft marked "IRWIN"

The most popular screwdrivers for jeep restorers are the ones where the

shank or shaft of the metal is stamped "IRWIN US of A - GOV.

STOCK #41-S-1076".

Wrench, Auto, Adjustable, 11 inches - #41-W-448 - An adjustable

wrench 11" long usually left in a natural oiled bare metal finish although

they are sometimes found painted black as well. This tool also doubles

as the leverage handle for the Hub Socket Wrench #41-W-3825-200 when removing

axle nuts. The wrench's handle slides into the slots punched in the Hub

Socket so that torque can be applied to tighten and loosen the wheel bearing

nuts. There were many tool manufacturers who made this wrench. When determining

if the 11" adjustable wrench you have is an actual jeep wrench, the most

important thing to look for in this wrench is that the wrench handle MUST

FIT INTO BOTH OF THE SLOTS on the Hub Socket Wrench. Most wrenches are

too thick to fit in the narrow openings on the hub Socket, while other

wrench handles only go through one hole on one side, but not both holes

at the same time because the many wrench handles gets thicker the higher

up the handle you go, so that it won't slide in far enough to make it to

the second hole in the hub wrench. You do not have the right wrench if

it doesn't go into both holes cleanly. Caveat: be sure the holes in your

Hub Socket tool haven't suffered an impact or dent. I have seen several

Hub Sockets that were only just slightly banged, but the bang resulted

in deforming (closing up) the hole enough that the 11 inch adjustable wrench

handle no longer slid in properly. Fairmount (Fairmont - I have one where

they miss spelled their own name), Diamond Calk, Diamond Calk "USN

- N.A.F." = US Navy - Naval

Air Facilities (less likely, but also possible... Naval

Aircraft Factory or Navy Air Forces), Lakeside, Billings & Spencer,

Barcalo Buffalo, and a couple marked with the #41-W-448 part number. (I

have them in both raised and recessed letters), and Vlchek. Most Vlchek

wrenches have a curved grip handle. These curved handle Vlcheks are for

the Dodge military vehicle tool kits. They are usually too fat to fit through

the holes in the Hub Socket Tool, however both during WWII and after, I

have been told, and found examples of curved handle Vlchek wrenches that

do fit in the Hub Socket tool holes because they were ground down in the

machine shop. Another example of the 'Semper Gumby' (Always Flexible),

CAN

DO spirit that helped to "KEEP EM ROLLING" when the correct

tool wasn't available. While not 100% correct for the factory fresh turn

key jeep restoration, these 'made to fit in the field' examples could be

displayed as correct for a 'combat ready' in service jeep restoration display.

Moore was another company that produced these wrenches for the military.

The GPW parts layout photo in the WWII Jeep manual clearly shows a Moore

12 inch adjustable wrench. I have found the Moore 12" adjustable wrench

in both black paint and bare metal as well. Even though the 12 in. Moore

wrench's handle is longer, it still goes though both holes on the Hub Socket

tool the same as its slightly shorter cousins.

Wrench, Brake Bleeder, Screw, Open End, Single sided - #41-W-1596-125

- A small short (3 1/2") one sided wrench stamped out of thin flat metal

rather than forged like the other wrenches. I have found the cadmium plated

wrenches with bare Cadmium finish as well as painted black and painted

OD. They do come marked in all 3 versions. Stamped with a:

-

Federal Sock #

-

Willys Part #

-

Ford Part # and a script "F"

Wrench, Crescent, 8 inches - #41-W-486 - 8 inch Adjustable Wrench

or Crescent Wrench was included in the prototype Ford GP, the early Script

Ford GPW, and the Slatgrill Willys MB Tool kits as well as the tool kits

for the standardized Willys MB and Ford GPW... at least up to the middle

of 1943. The 8" Adjustable Wrench is not listed in MB/GPW manuals as being

part of the tool kit in 1944 and 1945. However it is listed as being part

of the Motor Pool Mechanics tool kit. So this wrench should be displayed

as part of your 1941, 1942, 1943 GP, MB or GPW onboard tool set. Many companies

made them including: Barcalo Buffalo, Fairmount, JP Daniels, Williams,

Utica, Crescent, Diamond Calk, and others. Willys MB part #A-376. Ford

GP & Ford GPW part #GP-17023.

Wrench, Socket, Fluted Head Set Screw, "Bristol" type - #41-W-2459-500

-

Looking very much like a Allen Head Wrench, but it isn't. It is not hexagon

sided like an Allen Head, rather it has a star-like pattern of teeth like

a gear cut into it. The Fluted Head Socket Wrench was used to loosen the

set screws for removing, installing, or adjusting the shifting forks on

the shift rails in the MB/GPW T-84 Transmissions. It is a small "L" shaped

wrench/key 2 5/8" by 1" with a black oxide finish.

Wrench, Hub, Wheel Bearing Nut, (2 1/8" socket) - #41-W-3825-200

- This socket is used to remove the axle nuts to R&R the wheel bearings.

This is a very large socket made from approximately 2 1/2" round tube stock.

It is approx. 3 1/2" deep with one end being pressed into a hex shape to

fit the 2 1/8" wheel bearing nuts. The other round end has had 2 oval slots

punched into it to allow the 11" Adjustable Wrench to be used as a handle

and apply force to tighten and remove the nuts. Willys are painted dark

OD green and have the Willys part # stamped into it. The Ford as

"Ford" marked and have the Ford part # stamped into the unpainted surface.

The fed part # marked ones are found with what looks like a black oxide

finish.

Wrenches, Open End - 5 sizes of double open end wrenches were

kept in the tool roll. The lengths of the wrenches increased in size with

the size of the openings. Be wary of buying the many "FORD" script wrenches

offered. The size combinations are incorrect. The correct size combo's

are listed below.

|

#41-W-1012-5 |

|

3/4" |

|

by |

|

7/8" |

|

#731A |

|

approx. length 9" |

|

#41-W-1008-10 |

|

5/8" |

|

by |

|

25/32" |

|

#28-S or #28-D |

|

approx. length 8" |

|

#41-W-1005-5 |

|

9/16" |

|

by |

|

11/16" |

|

#27C |

|

approx. length 7" |

|

#41-W-1003 |

|

1/2" |

|

by |

|

11/32" |

|

#25 |

|

approx. length 6" |

|

#41-W-991 |

|

3/8" |

|

by |

|

7/16" |

|

#723 |

|

approx. length 5" |

Wrench, Drain Plug, Square, 3/8 - #41-W1962-50 - This tool was used

by shoving into the recessed square holes on gear housings' drain plugs.

This allowed a mechanic to get a wrench on the bar stock for greater leverage.

It is 3/8" square bar stock that is 2 1/2" long.

Wrench, Spark Plug, with Handle -#41-W-3335-30 -40

-50* (2/1944) - TM-9-803 - A tall hollow tube of round stock metal

that was pressed at one end into a hex shape to fit over and grip a spark

plug. At the top of the tube 2 holes have been punched for a 3/8' round

metal handle to be inserted. It appears that the suffix #'s were changed

for some reason. Different manuals call for different part #'s and sockets

exist bearing the different #'s. The fact that Ford offered an "A" suffix

leads to speculation that there was a first version with no suffix, then

a "A" version, and perhaps a "B" version as well. Heights and finishes

vary as well; 3" - 4" tall, and WO and Fed#'d ones exist. Black oxide,

silver cadmium, and OD paint finishes as well.

Wrench, Handle, Spark Plug - #WO-306715 / #GPW-17011-A - The

handle is nothing more than a solid piece of 3/8" round stock metal with

a single widened section at one end. The widened end keeps the handle from

sliding all the way through the 2 holes punched in the Spark Plug Socket

Wrench, Wheel Lug/Jack Handle - #41-W-3837-55 (41-W-3837-25) -

An 'L' shaped lug wrench approximately 10" long by 5" deep made from round

stock metal, with lug nut socket on short end. The long narrow round end

does duty as handle for vehicle jack. Note: Item # inconsistent between

manuals. #41-W-3837-55 is correct #. Originals are found painted

flat black, OD green, and silver.

Handles are found marked in 3 versions.

-

Federal #41-W-3837-55

-

Willys Part #A-348

-

Ford script

* Bolt, Square Head, Rear Axle Puller (4)

- 2 short square head bolts installed in 2 tapped holes on each rear axle

hub. To use, the 6 hub bolts were removed, and the 2 Square Head bolts

were then screwed all the way in. As the bolts passed though the axleshaft

hub flange, they hit the solid face of the hub. Since the hub wasn't going

anywhere, the flange would be drawn away and out of the hub allowing the

rear axle shaft to be removed from the jeep. This information comes from

several sources; Word of mouth from several motor pool veterans,

jeeps in the wild having them installed on the jeep when found, NOS examples

found in Jeep Dealers' inventory. I have found more late war jeeps with

these than early war jeeps. 4 per jeep. I at first thought they would be

stored in the tool roll since you would not want to snap one off, but I

was informed by the veterans that they threaded them in to the axle shaft

hub flanges and left them there because it was a common complaint that

those threaded hole, if left empty quickly filled up with hardened dirt

& grease from use and made it extremely difficult to clean out the

threads in the field. The fact that I have found jeeps in the wild with

them installed seems to prove the veterans right.

Special Tools - issued to

2nd echelon

** Compressor, Shock Absorber Grommet - #41-C-2554-400 (#MAS-1148

Monroe) - Used on WWII Army Jeeps to compress the rubber bushings into

the Shock Absorber mounting loops, so that a washer and cotter pin could

be dropped into the hole in the Shock Mount Stud welded on the jeeps. (Bantam

T-3 Jeep Trailers did not need this tool as they used a nut and threaded

Shock Mount Stud). Early Tools were made from brass, while later

tools were made from iron. See TM9-803, pg. 73. Only

a few would be issued to a group of jeeps. Motor Pool item.

** Lifter, Valve - #41-L-1410 - Valve Lifter Tool, Fed. Stk.

No. 41-L-1410 was the tool used to hold and compress the L134 engine's

valve springs while making adjustments to the jeep's engine. Only

a few Valve Lifting Tools would be issued to a group of jeeps as a Motorpool

item. They were used in conjunction with the Valve Tappet Wrenches.

These

tools, also known as Valve Compressors and Valve Spring Adjusting Tools,

were

made from stamped steel, with pot metal adjusting handles. This is the

tool that was used to adjust or to remove the valve springs in the WWII

Jeep Flat Head Engine. Valve Lifter Tool, #41-L-1410, was used on both

the WWII Willys MB & Ford GPW Jeeps, and it was also used on the Willys

MA, and Ford GPA. It continued to be used after the war on M-38 military

jeeps and civilian CJ-2A jeeps. It can be used on any vehicle with

the L-134 Flathead Jeep Engine. This is a great tool to have in your WWII

Motor Pool Mechanics Tool Kit or in your MB, GPW, MA, GPA, M38, Early CJ

Special Purpose Tool Kit. These tools were manufactured by several companies

with each brand slightly altering the design. The No. 675 made

by WILDE K. C. MO. (Kansas City, MO) followed by the patent number

underneath is one example. See TM-9-1803A Sec 6-7 Figure 10 and TM-9-1803A

Sec 18 Figure 32 for photos and instructions. A rare tool as only

a few would be issued to a group of jeeps. Motor Pool item.

** Wrench, Tappet, Double End, 11/32" by 17/32" - #41-W-3575 - only

a few would be issued to a group of jeeps. Army Motorpool item. Tappet

Wrenches #41-W-3575 were the tools used to adjust the L134 engine's

valve springs on the jeep's engine. Only a few Valve

Tappet Wrenches would be issued to a group of jeeps as a Motorpool item.

These

are the wrenches that were used to adjust or to remove the valve springs

in the WWII Jeep Flat Head Engine and were used

in conjunction with the Valve Lifter Tool # 41-L-1410. It takes 2

of these 11/32" x 17/32" wrenches to do the valve adjustments. Valve Tappet

Wrenches, #41-W-3575, were used on both the WWII Willys MB & Ford GPW

Jeeps, and were also used on the Willys MA, and Ford GPA. They continued

to be used after the war on M-38 military jeeps and early civilian CJ-2A

jeeps. They can be used on any vehicle with the L-134 Flathead Jeep

Engine. There are 2 known sets used in WWII for adjusting the valve

tappets on the L134 Flat head jeep engines. A darker gray parkerized set

with "41-W-3575" in raised letters in the center, and a light grey parkerized

or polished nickel chrome set MFG. by Lane Irons Works. The Lane Iron Works

set is marked with the 41-W-3575 stamped into the metal off to the side.

This is a great tool to have in your WWII Motor Pool Mechanics Tool Kit

or in your MB, GPW, MA, GPA, M38, Early CJ Special Purpose Tool Kit.

See MB/GPW Maintenance Manual TM-9-1803A Sec 18 Figure 33 which shows how

to adjust valve tappets. TM 9-803 under special tools, you will see the

41-W-3575 in there along with the measurements for the valve tappet wrenches.

A rare tool as only a few would be issued to a group

of jeeps. Motor Pool item.

***Chest, Tool, Mechanic's // Box, Tool, S., loose tray, olive drab,

enameled, 21" x 8 1/2" x 7 5/16" - #41-B-1833 replaced

by #41-B-1840 - (Portable Tool Box) - Stamped steel construction.

The manufacturer's name and Fed Stk # are often stamped

under the handles. Toolbox comes with a removable tray for sockets, etc.

Only

a few toolboxes would be issued to a group of jeeps. Army Motorpool item.

*** Pan, Oil Drain - Motor pool item, not stored on jeep. A

nice steel oval drain pan. A metal wire folding handle extends so you can

slide pan under and remove pan from under jeep. the bottom of the pan has

two metal runners or skids to protect pan bottom. The top of the

pan has a small mesh wire screen over it to catch any dropped bolts and

keep them from falling into the 5" deep oil holding tank. The top of the

pan is covered with slightly sloping sheet metal with a 2" hole at the

end. To use, handle is unfolded and the pan slid under the jeep. The jeeps

oil drain plug is removed and the oil streams down onto the mesh screen

which catches any debris. As the oil passes through the screen it goes

1/8" below the screen onto the top sheet metal. (There is a raised lip

of approx. 1/2" to keep the oil from over flowing to the sides).

The oil then travels down the slope to one rounded end where it enters

the drain hole and falls into the large capacity holding tank. The chamber

looks like it should hold enough oil for 5 or 6 jeeps. The oil filter can

be placed on the tank top to drain as well. the assembly is pulled out

by the long handle from under the jeep when finished. The long handle is

folded over the top for storage and 2 small grab handles on either end

can be used to carry the Oil Drain Pan to dispose of the waste oil.

*** Sockets Sets and Ratchets - Ratchets and Socket Sets were

issued to higher echelons and to other vehicles as part of the onboard

tool kit, but not the 1/4ton Jeep. It is interesting to note that in an

attempt to reduce theft loss of their tools during the WWII

war years, the US Government ordered their ratchets and sockets in a unique

drive size: 9/32nds. These 9/32" Drive tools do not interchange with

1/4" drive tools.

"War Finish" & "WF" Tools - At this point "WF" and "War

Finish" Tools should be mentioned.

Tools can be found marked "War Finish". These were tools made during

the World War Two years for civilian use, but were manufactured to a lesser

quality than the Co had produced them to during peacetime. Because of the

war, restrictions were placed on all manufacturing for the civilian market

in order that sufficient amounts of critical materials would be available

to meet the requirements of industry for the war effort. "War Finish" stamped

on a tool would be an indication that the materials used in the tool's

manufacture were of a lesser quality, due to those wartime scarcities.

"War Finish" tools usually carry the tool manufacturer's standard part

number.

"WF" is often equated to "War Finish", but evidence points to a different

meaning. The location of a major War Department contracting organization

before and during WWII was Wright Field (Wright, Patterson AFB now) which

is outside Dayton, Ohio. In addition to executing major contracts with

civilian industry, Wright Field also received & distributed goods to

the US Armed Forces throughout the world. "WF" more likely indicates Wright

Field. Many times a tool will have the letters WF as a prefix or suffix

of it's part # as stamped on the tool. This usually implies that the tool

was part of a contract initiated by Wright Field. The WF precedes the identifying

# on hundreds of thousands tools that were used by the Armed Forces during

WWII. These numbers did not correspond to the Mfg. co.'s stock number or

catalog number. Several surviving copies of the WW2 era catalogs refer

to the WF series tools as Wright Field Tools. Many tool companies stamp

their contracted tools with the name or abbreviation of the contracting

authority. Tools made under contract to the US Government during WWII were

not designed or manufactured with lifetime guarantee of service. They were

not guaranteed. Since they were only made to meet the government's specifications,

the manufacturer would not want to use their standard catalog tool number

which would imply a Lifetime Guarantee for the tool for years to come.

The majority of WF numbered tools, as well as some of the "War Finish"

tools made for civilian use during WWII have a light gray dusty finish.

This is sometimes construed to be what "War Finish" means. However, if

the words “War Finish” were just related to the texture and appearance

of the exterior, then stamping them with the words "War Finish" would be

both redundant, and an unnecessary added expense that would hardly seem

worth the extra effort since there was a war going on. The ardent tool

collectors firmly believe that “WF” and “War Finish” did not indicate the

color and texture of the tool. Saying instead that “WF” meant “Wright Field”,

the contract source and destination of the Government contracted tool.

“War Finish” on tools for the civilian market, or other wartime contracts,

was an indication that the materials used in the tool's manufacture were

of a lesser quality, due to wartime scarcities. - Ref.

Source #1 - Ref.

Source #2

Standard Issue Equipment &

Accessories

| Item Nomenclature |

Fed # /

MFG. # |

Willys # |

Ford # |

Storage Location |

| Apparatus, Decontaminating, M-2 (1 1/2 Qt. Sprayer) |

M-2 |

Item not supplied by the vehicle manufacturer.

Added to Jeep after the US Army had taken possession by "Other Technical

Services". |

Floor under Passenger Seat, in Bracket or elsewhere *9 |

| Ax, Chopping, Single Bit |

41-A-1277 |

Item not supplied by the vehicle manufacturer.

Added to Jeep after the US Army had taken possession by "Other Technical

Services". |

Body, Brackets on Driver's side |

| Bucket, Water, Collapsible |

|

Item not supplied by the vehicle manufacturer.

Added to Jeep after the US Army had taken possession by "Other Technical

Services". |

on Rear Gas Can, held by Gas Can Strap |

Drum, Inflammable-Liquid (Gasoline), Steel, with-Carrying-Handle, 5

Gallon or

Can / Container, Feul / Gas, 5 gal. |

42-D-1280 (post WW2 #MIL-C-1283) |

Item not supplied by the vehicle manufacturer.

Added to Jeep after the US Army had taken possession by "Other Technical

Services". Includes #64-C-291 Cap, can, 5 gal, w/Chain and cotter

key |

Carrier / Bracket / Rack on Rear Body, driver's side |

| Can, Water, 5 Gallon |

64-C-281 |

Item not supplied by the vehicle manufacturer.

Added to Jeep after the US Army had taken possession by "Other Technical

Services". |

Carrier/Bracket/Rack on 1) driver's side rear body, or 2) passenger's

side step |

| Covers, Headlight (2) |

|

A-3070 |

GPW-1102980 |

Under Front Passenger's Seat |

| Cover, Windshield |

G503-76-98476 |

A-3211 (A-3073)*13 |

GPW-1103214 |

Under Front Passenger's Seat |

Curtain, Body Side, Ass'y L. H.

(Canvas 1/2 Door) |

|

A-2998 |

GPW-1120041 |

Installed or Under Front Passenger's Seat |

Curtain, Body Side, Ass'y R. H.

(Canvas 1/2 Door) |

|

A-2999 |

GPW-1120040 |

Installed or Under Front Passenger's Seat |

| Deck, Top, Ass'y (Canvas Top) |

|

A-3216 (A-2909)*13 |

GPW-1152700 |

Installed or Under Front Passenger's Seat |

| Kit, First Aid |

Stock No. 9-221-200 or

Item 9777300 or "Gas Attack" |

Item not supplied by the vehicle manufacturer.

Added to Jeep after the US Army had taken possession by "Other Technical

Services". |

Bracket behind the Dashboard, between gauges & glove box |

| Mask, Dust, M-1 |

M-1 |

Item not supplied by the vehicle manufacturer.

Added to Jeep after the US Army had taken possession by "Other Technical

Services". |

Glove Box |

| Nozzle, Flexible Tube, Fuel |

|

Item not supplied by the vehicle manufacturer.

Added to Jeep after the US Army had taken possession by "Other Technical

Services". |

Left Rear Tool Box |

| Order, Lubrication Chart |

501 |

|

|

Glove Box, or after 11/1943, under hood *10 |

| Rifle Scabbard, Leather - Early |

|

Item not supplied by the vehicle manufacturer.

Added to Jeep after the US Army had taken possession by "Other Technical

Services". |

Various locations, suspended from leather straps |

| Rifle Rack, Universal, metal - Late |

|

A-11319 |

GPW-1153100 |

Inside Vehicle, on brackets on Outer Windshield Frame |

| Rifle Rack, Universal, (metal - Late) Canvas Cover, zippered |

|

A-12721 |

|

Inside Vehicle, covering Rifle Rack, metal strips & screws or staples

secure it |

| Shovel, General Purpose, D Handle, Round Point |

41-S-3170 |

Item not supplied by the vehicle manufacturer.

Added to Jeep after the US Army had taken possession by "Other Technical

Services". |

Body, Brackets on Driver's side |

| Spare, Tire, Wheel, & Tube |

|

A-465 |

GPW-1015 & GPW-1501 |

Body, Rear, from Carrier Bracket / Rack on Pass. side |

| Spare Tire Lock & Lug Nut |

|

A-1319 (Lock) & A-1318 (Nut) |

|

On one of the spare tire studs |

Book, Maintenance Manual or

Book, TM 9-803 |

TM 9-803 1944-1945

(TM 9-1803A, TM 9-1803B) |

several Willys TM's issued 1941-1943 |

several Ford TM's issued 1941-1943 |

Glove Box, or Inside Cushion Under Driver's Seat *11 |

Book, Parts Manual or

Books, ORD 7 & 9 SNL G-503 |

ORD 7 & 9 SNL G-503

(ORD 8 SNL) 1944-1945 |

several Willys TM's issued 1941-1943 |

several Ford TM's issued 1941-1943 |

Glove Box, or Inside Cushion Under Driver's Seat *11 |

| Form, War Dept., AGO 478 |

|

|

|

Glove Box, or Inside Cushion Under Driver's Seat *11 |

| *Cover, Mirror |

|

|

|

Installed or Under Front Passenger's Seat *12 |

| *Lock, Pad, Brass (2) |

|

Item not supplied by the vehicle manufacturer.

Added to Jeep after the US Army had taken possession by "Other Technical

Services". |

Installed or Glove Box *12 |

*9 ~ several other mounting locations also

authorized: Back of Left or Right Fender; Between Driver's Seat Back &

Body; Top of Rear Fender (inside vehicle).

*10 ~ several versions were made. Early

ones were stored in the glove box, later ones in field made brackets, and

late one in factory holders.

*11 ~ several versions were made. Early

Slatgrill MB ones were stored under the driver's seat in a zippered compartment,

later ones in the glove box.

*12 ~ Word of mouth, jeeps in the wild

having them on, NOS examples found in Surplus Dealers' inventory, photographic

evidence

*13 ~ The 1st 3545

Willys Slatgrill Jeeps had a shorter windshield, so It had different part

#'s associated with it.

Apparatus, Decontaminating, M2 - The M-2 Decontaminator was a

1 1/2 Qt. approx. 18" long brass or copper liquid pump sprayer, made by

several manufacturers. Labels Can be found in brass, copper, steel, decals,

and paper. They are painted a blue-gray color, or can be painted over with

OD Green (camouflaged) or a bright yellow for "Follow Me" Jeeps as the

case warranted. Photo

of blue-gray decontaminator next to several rare "Ford" script Fire Extinguishers.

They mounted in a special bracket very similar to a fire extinguisher bracket.

It's purpose was to render neutral and wash away, poison chemical gas residue

such as Mustard gas, Phosgene, etc. After a soldier put on his own gas

mask, and gas protective cape, he would spray down the jeep by pulling

out the handle and pumping, paying special attention to soak the seat and

area of the jeep that require human contact to operate the jeep. After

waiting 15 minutes a second coating was applied. After the second application

had dried, the jeep or vehicle was now considered operable in an emergency.

Although this was not a thorough cleaning, it would allow the soldiers

some chance of being able to drive away from the scene of a gas attack.

The decontamination unit was often used in conjunction with chemically

reactive paint. This was a special paint manufactured for the Chemical

Warfare Department and was applied in specific areas to provide a visible

warning in case of an attack by the enemy using "chemical weapons" such

as mustard gas or other blistering agents. The color of the paint

would change drastically - usually to a dark brown - when it came in contact

with fumes from a chemical weapon. The special paint was applied to the

hood at the National Symbol (US = 5 pointed star). Most often seen on Mid-Late

war jeeps where the Star & Surround (the circle around the star) are

painted white, and the area Between the star & surround are

painted with the special gas detecting paint. If you look closely

at original B/W photos, you will often notice that the gray (OD paint)

inside the surround is a different shade than the gray (OD paint) on the

rest of the body of the jeep. This is because it isn't the same OD

paint, it is in reality the special "Gas Detecting" paint. Gas detecting

paint was used both at the front lines and in the rear areas as this photo

of a WWII Air Base "Follow Me Jeep" shows. Here is an original

color picture of a group of world war two jeeps on a landing craft about

to storm the beaches during an invasion, all jeeps have the interior

of the Surround painted in chemical reactive paint aka gas detecting paint.

Bracket, Apparatus, Decontaminating, M2

- The M-2 Decontaminator was mounted in a special bracket very similar

to a fire extinguisher bracket. There are 4 types of brackets made by various

companies. The brackets were usually supplied with the decontaminator by

the Chemical Warfare Service, US Army and had several correct mounting

locations. Composite body jeeps had the mounting holes pre drilled for

the bracket at the factory. The standard factory position was to mount

it under the passenger seat on the floor behind the right seat along the

riser to the rear floor pan. Screws, washers and nuts plugged the holes

until needed. There are several other correct mounting positions.

Other mounting locations authorized: on the back slope of Left Fender or

Right Fender; Between Driver's Seat Back & Body; Top of Rear Fender

(inside vehicle). There is a manual that details the correct position

for mounting a Decontaminator (also know as a Decontamiator Device) and

bracket depending on what branch of service the jeep was attached to, and

what other equipment existed on the jeep.

Ax (axe), Single Bit, (Pioneer Tool) - #41-A-1277 - The blade

slips into a metal sheath welded to the jeep body tub. The Mall (fat end)

of the ax rests in a hinged bracket that is held in place by a strap. Ax

handle fits through a loop bolted to the body of the jeep. The 4lb axes

were made by several companies. Military axes usually have squared corners

on the mall face, while civilian ones have rounded corners. Ax head and

handle should both be painted OD green. Axes came

in different blade-to-head lengths. The early jeeps, both Ford Script GPW

and Willys Slatgrill MB took an ax bracket with only 2 mounting holes.

The flat steel section of the mounting bracket was shorter than the standard

jeep ax bracket. Early in 1942 the mounting section was lengthened

to accommodate 2 extra mounting holes that were added to allow the bracket

to hang lower on the jeep allowing longer ax heads to be mounted. The ax

blade slipped into a metal sheath that was spot welded to the side of the

jeep's body tub. Photograph

showing standard 4 holed ax bracket and ax sheath. Notice incorrect

number of footman loops. 3 is correct, 4 is not.

Ax Strap - The ax strap is fastened

to the top footman loop with the buckle facing forward. The strap runs

down through the metal ax bracket wire loop and then back up into it's

own buckle. Photograph

showing correct running of ax and shovel straps. Notice

correct number (3) of footman loops.

Bucket, Water, Collapsible - Jeeps were issued with a collapsible

Water Bucket folded up and stored on the rear gas can. See TM9-803 Feb.

1944, page 67, 3rd item. The water bucket has two straps "X" along the

bottom. The gas can strap goes under the gas can metal handles, over

the canvas water bucket body and under the water bucket's canvas "X" straps,

and then meets the buckle of the other gas can strap. This secures the

Water Bucket between the gas can and gas can strap.

Photograph

of a 1943 Ford GPW Army Jeep with water bucket.

Picture

of a 1942 Willys Slatgrill, as seen in this photo, the USMC used water

buckets too.

Can, Gas / Container, 5 gallon ~ AKA ~ Drum, Fuel,

5 gal. ~ AKA ~ Gas Can / Jerry Can / jerrican / blitz can / jeep

can

Officially "Drum, Inflammable-Liquid (Gasoline),

Steel, with-Carrying-Handle, 5 Gallon"

Early Flimsies

& Round Gas Cans - Army gasoline cans were originally, cube shaped

ones called "Flimsies", or round barrel shaped cans. The Flimseys were

notorious for leaking. The handles were wire loop style and folded flat

into the recessed hand hold. They had either flat or corrugated side panels

and appear to be galvanized. They are marked with stamped letters

re: procurement agency they were issued to. I have one each marked:

"U. S. A.", "U. S. N.", "A. A. F.". I

have not seem a USMC marked flimsey - as of yet.

British &

German Gas Cans - Germany is credited with designing a better portable

gasoline storage container. Their design would minimize the loss of fuel

during supply and battle. Developed under secrecy, the final version

consisted of two halves, welded together and it had "X" impressions on

the side panels which made it stronger than the earlier fuel containers.

Another very important feature were the 3 handles at the top. The 3 handles

would: 1) Let one man carry two cans and hand them over to a second man.

2) Let two men to carry one can between them. 3) Make it easy to pass cans

along in a "bucket brigade" (passing the containers from one man to the

next). The center handle was for carrying by an individual soldier, the

two on either side were used for teamwork applications.

The filler tube and cam lock cap of german design is also clever. It

is designed with an internal air pipe from the pour neck to the air pocket

which allows for even and constant flow when emptying. Due to its built

in air pocket, the gas can will float in water if dropped, even when full

of fuel. It had room for 20 liters of liquid and it weighed approximately

20.5 kg when full. The British named the "Jerry" can after the Germans.

"Jerry" was a slang term the Allies had for the Germans during the World

Wars.

Early US Gas Cans

of British/German style - The US saw what the Germans, and shortly

thereafter the British, were doing with stackable, compact, easily handed

from person to person in a "Bucket Brigade" fashion "jerry can" style of

gas can. The US quickly went into production making copies of that

style. It appears that some of the very earliest US produced cans were

in fact Exact copies of the half seamed, cam lock British / German

style cans. They were not marked or dated, so you can't tell when they

were manufactured. These cans have an "X" reinforcement stamped into both

side panels, but not the indented square portion in the center common to

the English and Nazi cans. There are quite a few early WWII photos around

showing these type of gerry cans in use by marines in the pacific as well

as by the Army in N. Africa & Europe. These are the so called 'Mystery

Cans'.

Standard US WWII

Gas Cans - #42-D-1280 - US companies quickly redesigned the way the

can was manufactured and standardized it. The US version was a quickly

produced machine made version, that differed slightly from the UK/German

style which was 2 halves stamped and then welded together. This UK/German

version lent itself to be produced in smaller shops, but fewer units could

be produced per hour. The US version required large machinery, but the

production capacity was greatly improved. The US version has a bottom,

a top, a rolled and welded side, and welded on handle assembly. US

standard cans were 1st made in 1941. Many of the first cans were galvanized.

These cans are stamped with the dates on the bottom along with the manufacturers

name. In addition, the fluid capacity is also shown in both standard

and metric values. The manufacturers varied ever so slightly on how

they determined the fluid capacity, so cans will vary from each other in

the fluid capacity stamped into the bottom. The 5 refers to 5 gallons.

The 20 refers to liters. They listed metric values because gas cans were

part of "Lend Lease" sent to Russia, China, Canada, Australia, India, England

and other far flung regions. ICC is the Interstate Commerce Commission.

Gas cans fell under their jurisdiction, so all gas cans were required to

show the volume of gasoline capacity along with I.C.C. Water was

not under ICC jurisdiction, so most water cans are not stamped

ICC.

The Jerry Can unit consists of several components;

-

the can body with 3 handles

-

the 4 ear (2 ear on early cans) screw-in lid/cap

attached by a metal loop, chain, and cotter pin (chain & rivet on early

cans)

-

a rubber (asbestos on early cans) gasket that made

the seal between the lid and the can

-

a gas can octane tag that would tell later users

what type of fuel was in the can

Each of these subparts was available as a separate

supply item so that lost or damaged parts could be replaced.

Early Cans - 1941, 1942

Late Cans - late 1942, 1943, 1944, 1945

Early differences in Gas / Jerry / Jerri / Blitz

cans

-

Galvanized steel construction (came unpainted but

were usually painted when mounted on a vehicle)

-

Two eared screw on lid

-

Cap chain riveted to the can handle

Late differences in Gas / Jerry / Jerri / Blitz cans

painted normal steel construction

Four eared screw on lid

Cap has metal wire loop attached to chain, then cotter

pin attaches it to the can handle

WWII gas cans can be quickly spotted among postwar cans by the following

method.

WWII cans have "U.S.A." on one side (for US Army - USMC, USN also produced),

and "Q.M.C." stamped on the other side (for Quarter Master Corps).

Post war cans are usually found with "US" stamped on both sides.

USMC Gas Cans

- 90% of the cans I find marked "USMC" are NOT "US Marine Corps"

cans, but instead a postwar can made by United States Metal Corp. They

are still in business today stamping USMC cans. I see people often selling

them as Marine Corps cans. Real USMC cans have a small cam-lock style lid

like the german type gerricans. This allows for better pouring when a nozzle

or funnel isn't handy. Real USMC cans are manufactured and dated like the

normal gas cans. I have seen U. S. M. C. cans dated 1943, 1944, 1945.

I have encountered a few "USN" marked jerricans as well.

Gas Can Caps - #64-C-291

Caps, can, 5 gal, w/Chain and cotter key -

The 1st style (Very Early) caps made in 1941, and early 1942 had only

2 straight raised ears to use when opening/closing the can cap. Cap

is secured to gas can by a riveted on chain.

The 2nd style featured 4 straight raised ears to use when opening/closing

the can cap. Cap is secured to the gas can

by a metal loop, chain and cotter pin.

The 3rd style featured 4 round rolled raised

ears to use when opening/closing the can cap. Cap is secured to gas can

by a metal loop, chain and cotter pin.

Early water cans also had the same caps and attachment

method. One source states that during World War II Rieke Metal Products

Corp. made the military gas can lids and that Auburn Rubber Company made

the gaskets. I'm sure there were several other companies making both as

well.

The gas can spout (see below) was used as a tool to open and close

the gas caps on a can. The nozzle was laid sideways on top of the cap with

the flexible metal tube engaging the raised ears on the can's cap increasing

the leverage force available to open or close the gas can cap. Early

in the war gas cans only had 2 raised ears on the gas can caps. By early

1942 it was noticed that sometimes the 2 ears of the gas can lid aligned

in such a way that they were in a position where the filler tube could

not

be used to loosen a stuck closed gas can lid (cap). Having more ears would

solve this problem, so 2 more ears were added to the gas can caps by mid-1942

and gas can lids have come with 4 ears ever since.

Gas Can Spouts ~ Nozzle, Flexible Tube,

Fuel - Flexible metal spouts were issued to transfer

the gasoline into the various vehicle gas tanks. The most common issue

spout is the one for the standard American style gas cans. For the standard

US type large mouth Jerry Cans, a flexible spout was issued (also called

the donkey dick or donkey dong by irreverent GI's). The flexible coiled

metal spout diameter is about one inch; a far larger diameter than most

of the civilian gas can spouts made today. WWII GI ones were made to fit

the wide-mouth gas tank openings and filler tubes of military combat vehicles.

Larger diameter meant faster filling and less time being vulnerable as

a "sitting duck". This larger diameter also means it won't fit in the 'restricted

for unleaded gasoline only' gas filler openings on modern American civilian

vehicles. The spout is usually ~16 inches long from the end of the screw

on cap holding the brass screen filter to the end of the base. The WWII

flexible pouring spout had a screw-on cap with a deep soldered cone or

"V" shaped strainer over the end. The WW2 spout cap end should have a screw

on 3-4" long soldered brass funnel. This V-shape had a larger surface area

than a flat brass filter would, meaning it would allow more gas to pass

though before it needed to be cleaned. This cap filter is in addition

to the Fuel Filter and the fuel pump strainer found on the jeeps and military

vehicles themselves. Post war manufactured spouts have a flat or a concave

domed brass screen strainer. The MILITARY gas can pour spouts did not screw

into the threads of the jerry can opening. Instead, at the base of

the spout was an rubber expansion seal (a ring of rubber) and a lever that

would compress and therefore expanded the ring outwards sealing the spout

to the can when the lever was pushed down away from the body of the spout.

The spout base was pushed into the opening of the gas can, the lever pushed

down, and the rubber seal ring was pushed tight up against the threaded

opening to create a seal. That seal was often leaky, but the design was

not changed. Another feature of the base is that it has a stepped lip that

keeps the spout from falling into the can before the cam lever is pressed

down to expand the seal. The lip was designed to not be as wide as the

jerry can lid / cap. This way it doesn't cover the breather hole in the